Synergy Additive Manufacturing Awarded Phase I SBIR

Synergy Additive Manufacturing LLC Awarded Phase I SBIR by US Navy to Develop Advance Coating Solutions for Critical Naval Applications Clinton Township, MI – [June 2025] Synergy Additive Manufacturing LLC has been awarded a Phase I Small Business Innovation

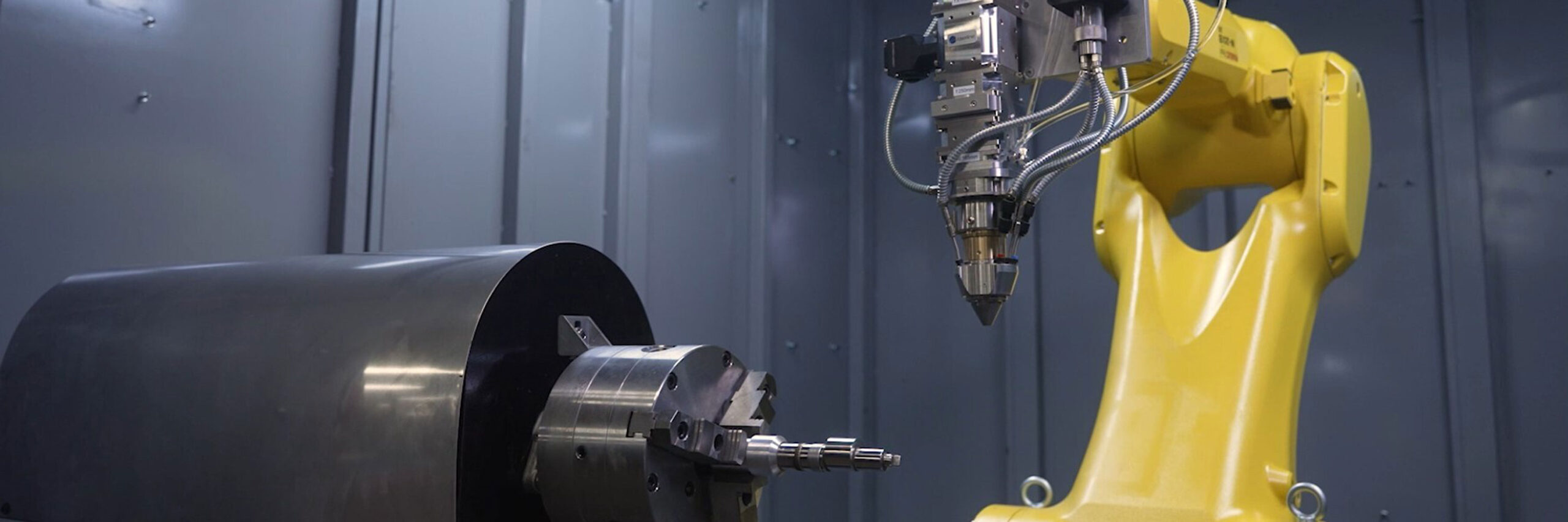

Laser Hardening Process

With experience in laser hardening over 500 large automotive castings and tools, Synergy has built a reputation for excellence. Beyond automotive tooling, our expertise spans industries such as mining, oil & gas, and aerospace. Our carefully optimized process ensures

Rockit 606®️ Overlays for Agricultural and Mining Industries

Rockit® 606 is an Iron (Fe) based hardfacing alloy produced by Hoganas. It is an Fe-Cr-V based alloy known for its high impact and abrasive wear resistance. The composition of this material is shown in the table below.

Laser Hardening of AISI D2 Tool Steel: A Modern Approach

Laser hardfacing involves using a laser to apply an overlay of hard and wear-resistant material onto functional surfaces. This process enhances the performance and durability of components, making them better equipped to withstand wear and tear. There are various techniques for overlaying metals and hardfacing critical components. Every industrial process possesses its own distinct characteristics and advantages. In this blog post, we will delve into the advantages of utilizing laser cladding technology for hardfacing with Tungsten Carbides. Additionally, we will provide detailed answers to common queries related to this advanced process.

Robotic Laser Cladding: A new way to repair High Pressure Die Casting Tools

High-Pressure Die Casting (HPDC), also known as High Integrity Die Casting, is a versatile and highly efficient manufacturing process that plays a critical role in producing complex structural components across various industries. Commonly used materials include zinc, aluminum, magnesium, copper,

Tool Path Programming vs. Manual Touch-up in Robotic Laser Hardening

Laser hardening has gained significant traction in the United States, becoming a favored method among OEMs and smaller tool and die makers. Each die is unique, requiring the laser to follow precise paths at specific angles and orientations to ensure quality. Robots are commonly used for this process due to their flexibility. This article explores two primary methods of robotic programming used in laser hardening operations and highlights the advantages of one approach over the other.

Heat Treat Today Publication: Advantages of Laser Heat Treatment, Part 2

Part 2 of our April 2024 article, published in June 2024, delves into the groundbreaking benefits of laser heat treatment. This innovative technique uses high-energy lasers to precisely and locally heat metal surfaces, forming a durable martensite layer up to

Advantages of Laser Heat Treating: Precision, Consistency, and Cost Savings

Our article, featured on Heat Treat Today’s website in April 2024, explores how laser heat treating is reshaping production in the automotive industry. This advanced technique addresses the distortion issues common with traditional methods, providing unparalleled precision and reducing the

Heat Treat Today Publication: Laser Hardening Automotive Case Studies

Our latest article, featured in the August 2024 Heat Treat Today magazine issue, explores the revolutionary impact of laser hardening on the automotive industry. Laser hardening is transforming the automotive industry by applying high-energy lasers to precisely heat metal surfaces,

Laser Hardfacing with Tungsten Carbide

Laser hardfacing involves using a laser to apply an overlay of hard and wear-resistant material onto functional surfaces. This process enhances the performance and durability of components, making them better equipped to withstand wear and tear. There are various techniques for overlaying metals and hardfacing critical components. Every industrial process possesses its own distinct characteristics and advantages. In this blog post, we will delve into the advantages of utilizing laser cladding technology for hardfacing with Tungsten Carbides. Additionally, we will provide detailed answers to common queries related to this advanced process.

Laser Cladding vs. Thermal Spray: Understanding the Strengths

Laser Cladding and Thermal Spray are two distinct techniques used to enhance surface properties in various industrial applications. Both technologies are effective for hard-facing, corrosion resistance, and dimensional restoration, but they each offer unique advantages. This blog delves into the strengths and ideal uses of Laser Cladding and Thermal Spray processes.

Stellite 6 Overlay With Laser Cladding

Stellite™ 6 is a cobalt-based alloy renowned for its exceptional performance in high-temperature wear and corrosion resistance. Composed of 27%-32% chromium, 4%-6% tungsten, 1%-2% carbon, 3%-4% nickel, 1%-2% silicon, 3%-4% iron, and the balance being cobalt, this material maintains its hardness

Press and Heavy Equipment Repair with Laser Cladding

In the world of heavy equipment maintenance, efficiency and precision are paramount. When it comes to repairing press components like bearing journals, hydraulic rods, and gears, traditional methods such as TIG, MIG, or submerged arc welding have long been the

Repair and Restoration of Rotating Equipment Using Laser Cladding Technology

Laser cladding is a technique used to repair and enhance the surface properties of rotating equipment. It involves using a high-powered laser to melt and fuse a coating material onto the substrate of a component. This method is particularly useful

Laser Hardening of Press Brake Tooling for Enhanced Performance

High precision press brake tools are essential for the metalworking industry, providing the necessary precision and durability for bending and shaping sheet metal. These tools are crafted from a variety of materials, including 4140, 4130, S7, A2, and D2 steels,

Repair of Decanter Centrifuge Components

Repair of Decanter Centrifuge Components Centrifuges are commonly used in medical, manufacturing and waste processing fields. They use a process that accelerates heterogeneous mixtures into components based on different densities. Density compares the amount of matter an object has to

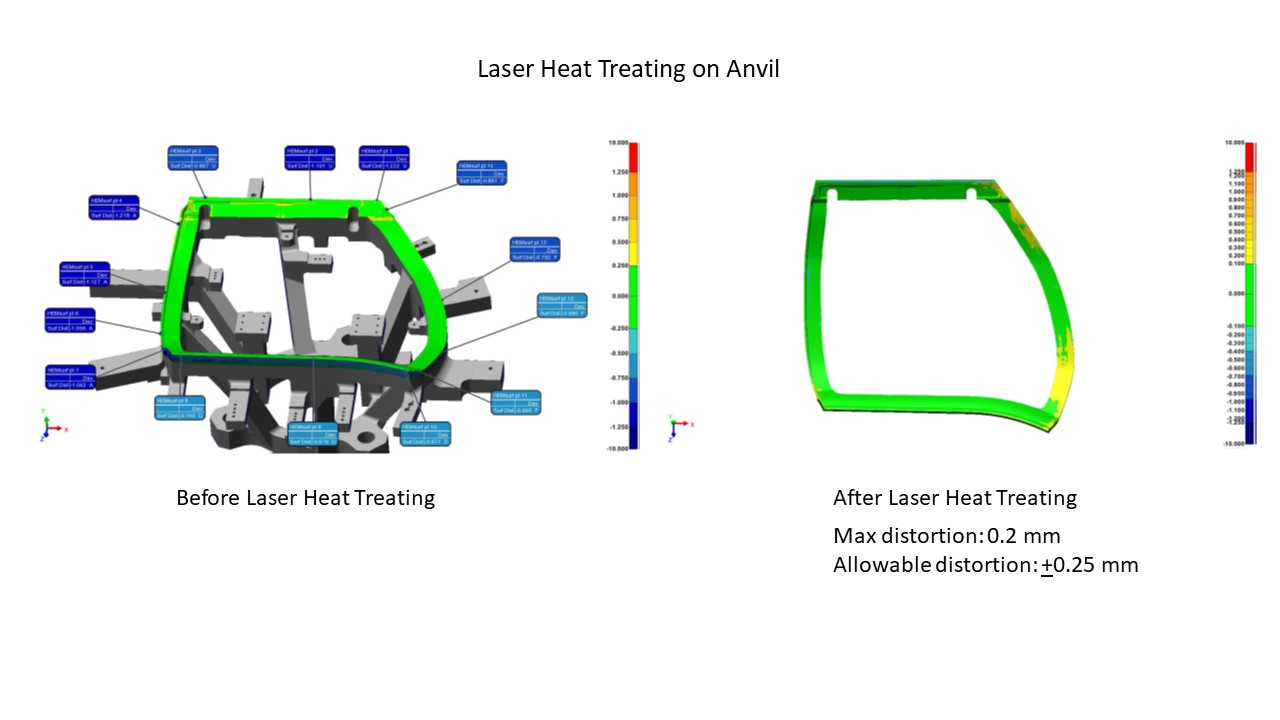

Enhancing Trim Die Performance with Laser Heat Treating: Synergy’s Cutting-Edge Solutions

In the competitive landscape of manufacturing, efficiency, quality, and cost-effectiveness reign supreme. At Synergy, we understand the challenges faced by die makers in delivering high-performance trim dies while managing costs and turnaround times. That's why we've harnessed the power of

Laser Heat Treating: A New Cost-Effective Approach to Trim Die Construction

In trim die build, where precision, efficiency, and quality are paramount, the adoption of laser heat treating represents a significant leap forward. This cutting-edge technology not only cut costs and turnaround times but also ensures unparalleled consistency and durability of

Revolutionary Breakthrough: Synergy Unveils Cutting-Edge Laser Hardening Technology for Trim Dies

Conventional heat treating process for trim dies involved leaving an extra stock of material on the die, which was then subjected to induction or flame heat treating. After heat treatment, the dies were machined back to the required tolerances. While

Laser Heat Treating of Guide Ways and Machine Rails

Laser heat treatment is indeed a viable alternative for improving the efficiency, safety, and precision of guide rail manufacturing processes. Laser heat treatment offers several advantages over conventional methods such as flame or induction heat treatment. One of the key

Repairing Large Critical Components using Laser Cladding

Were you aware that Synergy has the ability to repair large components? Recently, a flywheel with a diameter of over 1 meter was ground too much (0.015"/0.4mm) during prefinal operation, which was only discovered after nitriding. Scrapping the part would

Repair and Refurbishment of high precision shafts using Laser Cladding

Shaft laser cladding is a highly effective process for the repair and refurbishment of industrial machinery components such as precision tools, motor shafts, centrifuge components etc. especially those that have suffered from wear and tear or corrosion. This process uses

Laser Heat Treating on Hem Dies: An Innovative Solution for Automotive Production

The automotive industry is constantly seeking new and improved methods for producing high-quality vehicles. Hemming is a critical operation in the production process and has a significant impact on the overall quality and performance of a vehicle. Hemming involves

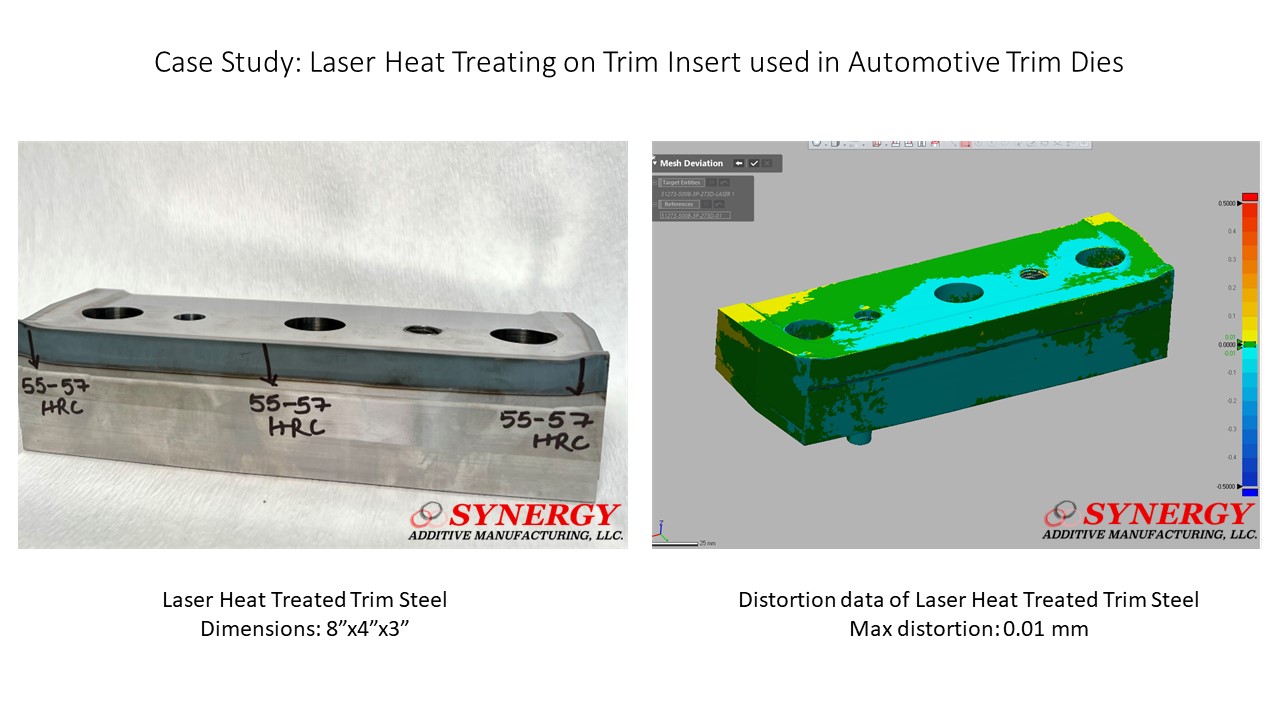

Laser Heat Treating of Trim Inserts for Automotive Dies: Improving Performance and Consistency

In the automotive industry, trim inserts play a crucial role in the production of sheet metal stampings. Trim steels are used to trim the metal sheets after forming operation. To ensure that the trim inserts are strong and durable,

Synergy Additive Manufacturing LLC Speaks at Metal Stamping Technology Conference

Join us January 24-25 at the Metal Stamping Technology Conference in Nashville. Synergy Additive Manufacturing LLC's CTO and Co-Founder, Aravind Jonnalagadda will cover case studies on how manufacturers can reduce overall costs, and time to market while significantly improving quality. Register