The automotive industry is constantly seeking new and improved methods for producing high-quality vehicles. Hemming is a critical operation in the production process and has a significant impact on the overall quality and performance of a vehicle. Hemming involves bending the edge of a sheet metal over itself, and it is performed on various components such as hoods, doors, tailgates, and fenders. Hemming dies, also known as anvils, play a crucial role in this process and are compact compared to conventional stamping dies, but this presents a new set of challenges for die makers.

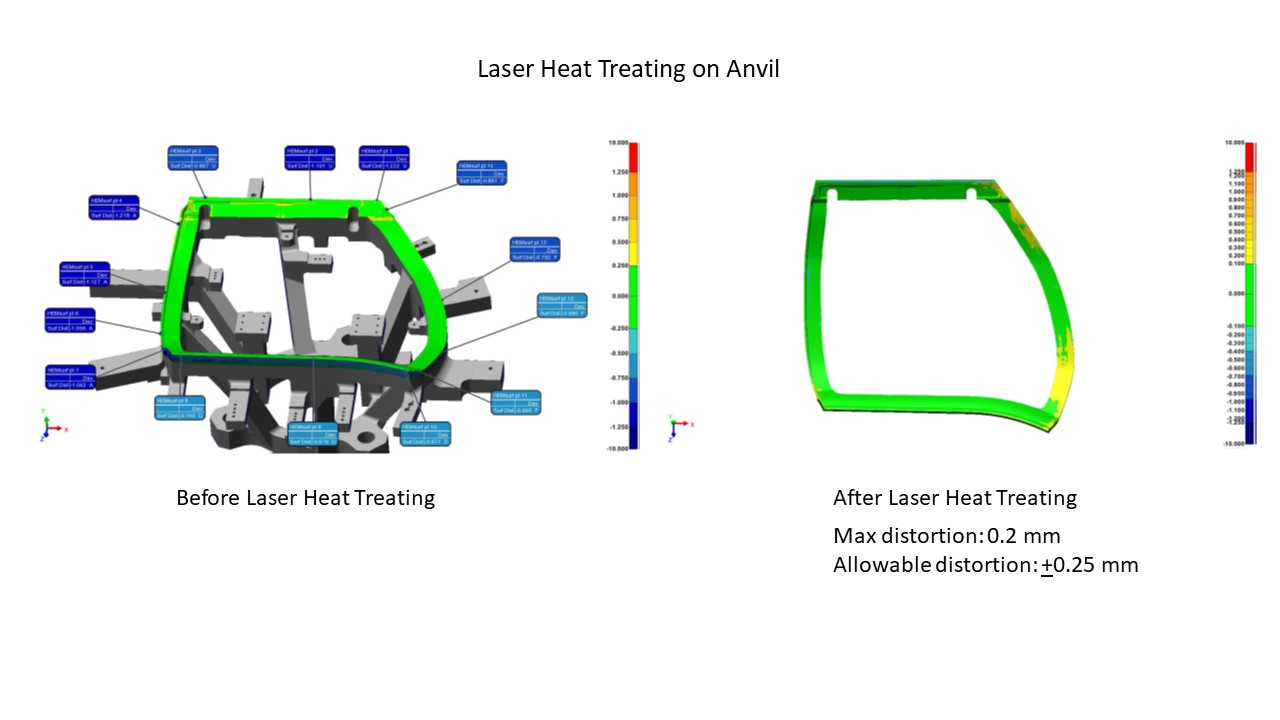

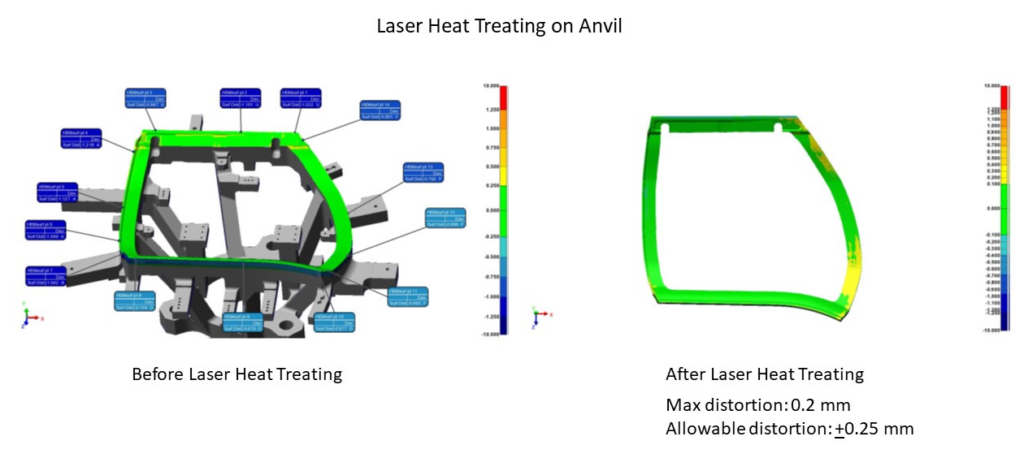

Conventional heat treating methods such as induction and flame can cause substantial distortion in hemming dies and result in inconsistent hardness across the profile. Additionally, the dies require a great deal of post-machining to bring them back to the desired tolerance. This not only results in substantial cost but also adds time to the production process, leading to increased Time to Market (TTM).

Laser heat treating offers a solution to these challenges and helps to maintain the quality of hemming dies. With Synergy’s laser heat treating process, the die is laser heat treated after it is machined to its final dimensions, resulting in minimal to no distortion and consistent hardness. This eliminates the need for additional hard milling processes and helps to reduce the TTM. Extensive testing by Synergy’s customers has shown that laser heat treated anvils exhibit consistent hardness within +/- 1 HRC and do not require additional hard milling operations.

In conclusion, laser heat treating is an innovative solution for the automotive industry, offering a number of benefits over conventional heat treating methods. It helps to maintain the quality of hemming dies, reduces TTM, and results in substantial cost savings for die makers and the automotive industry. If you’re looking for a reliable and efficient solution for your heat treating needs, Synergy is your go-to partner.