RAPIDLY REPAIR & REDESIGN CRUCIAL COMPONENTS

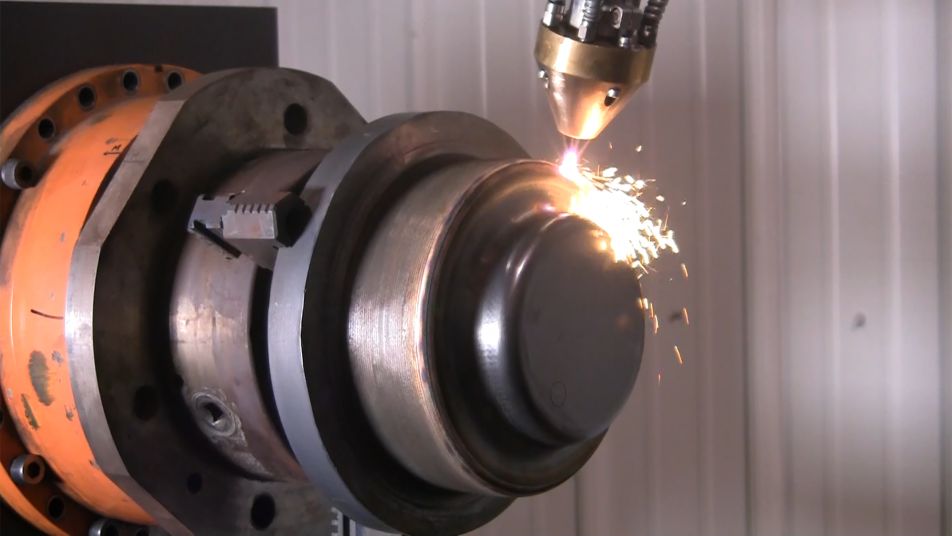

Remanufacturing with our laser services, allows clients to repair crucial components needed with extreme urgency to keep operations up and running. While turnaround times for newly remanufactured components can take anywhere from weeks to months, laser remanufacturing can repair worn out components with improved quality and strength in radically less time. Additionally, remanufacturing can be utilized to help reduce production lead times. Our laser additive manufacturing service can deposit additional material allowing parts to conform to dimension tolerances.

CASE STUDY: AUTOMOTIVE STAMPING DIE REMANUFACTURING FOR MODEL YEAR DESIGN CHANGES

- Model year changes often require complete die rebuilds.

- Prototype tooling often requires quick turn around.

- Die design changes using Synergy’s laser additive manufacturing process results in cost savings and reduced lead times.