For the oil & gas industry

- Laser hardfacing of drilling components

- Corrosion resistant coatings

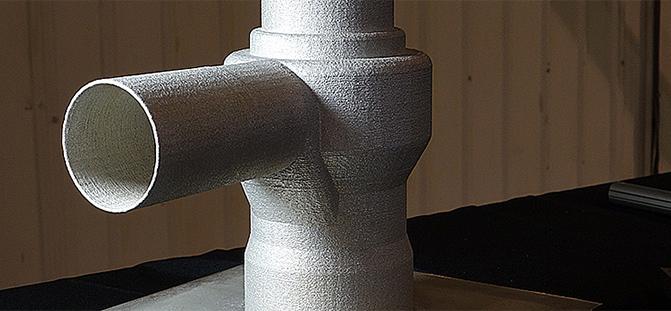

- 3D printing / Additive Manufacturing of complex parts

Capabilities:

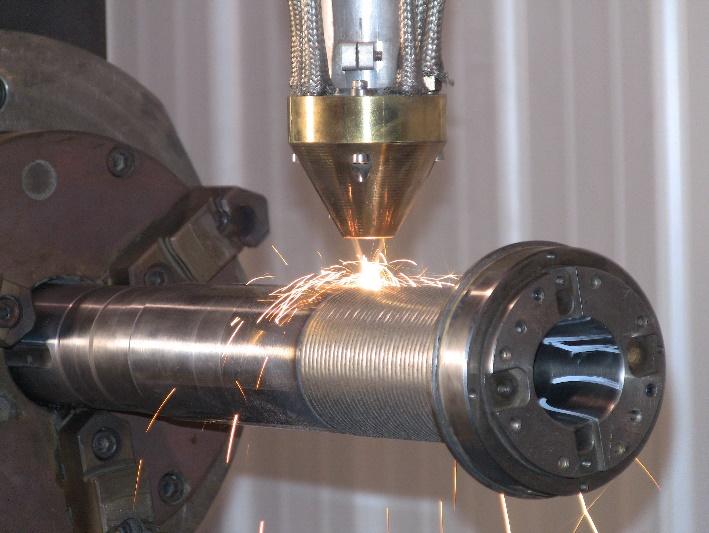

- Shafts ODs up to 5 ft diameter x 20 ft long

- ID as low as 3.5”; Lengths up to 40″ ; Greater lengths may be possible on request

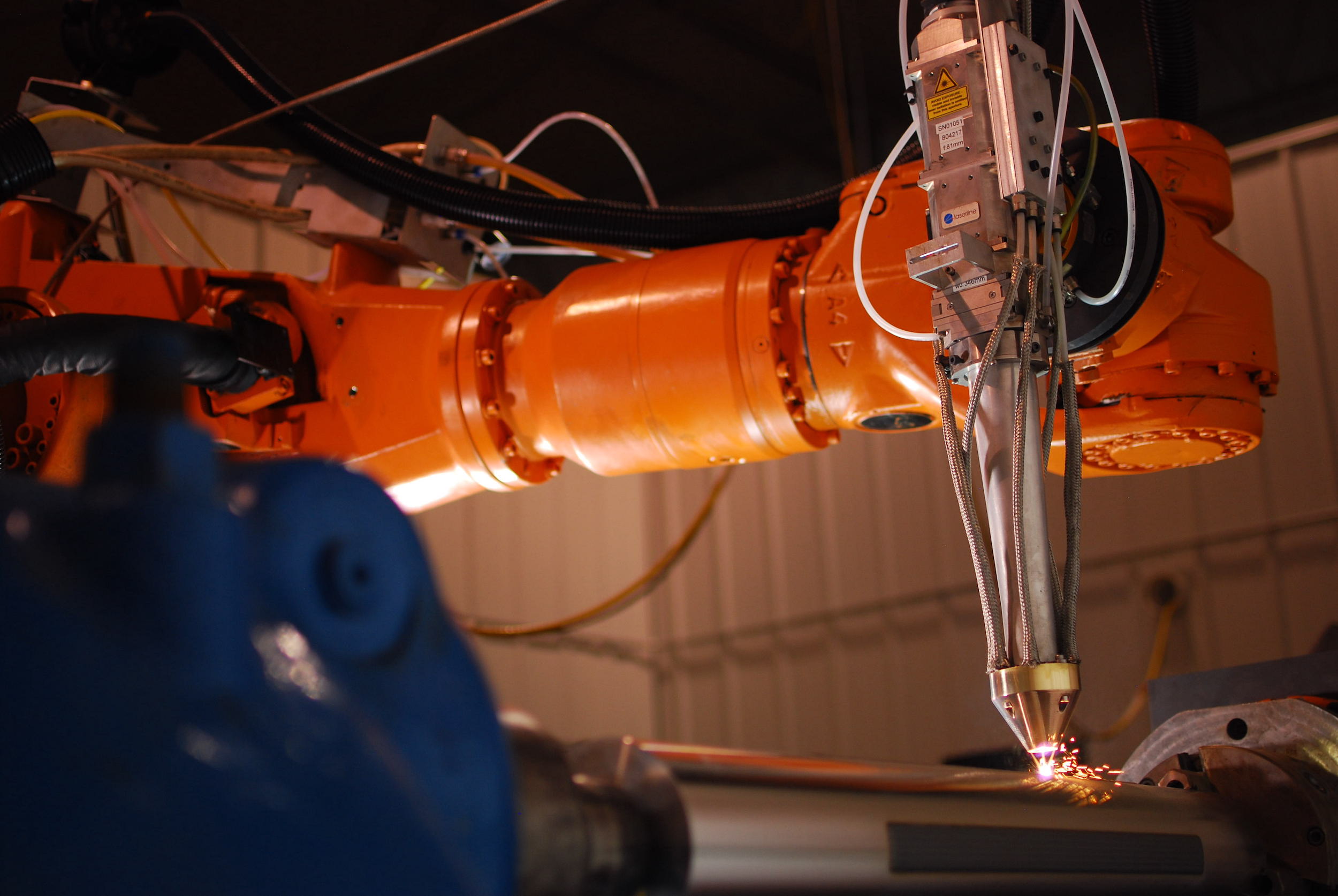

Hardfacing of oil and gas parts

Hardfacing is a process of applying high hardness materials such as Tungsten Carbide over a substrate material for enhanced wear performance.

The benefits of laser hardfacing compared to conventional GMAW, TIG or PTA include:

- Higher hardness of coating material compared to other techniques

- Low heat induced distortion

- Minimal Heat Affected Zone [HAZ]

Hardfacing Materials

Synergy Additive Manufacturing LLC offers a variety of material choices for hardfacing, including:

- Spherical and Angular Tungsten Carbides

- Cobalt-based alloys such as Stellite 6 and Stellite 21

- Nickel-based alloys such as Colmonoy 56 and Colmonoy 88

Corrosion Resistant Coatings

Laser cladded corrosion resistant coatings provide unique benefits when compared to traditional techniques. The localized heat input resulting from the use of lasers results in minimal dilution of base materials. This results in minimal iron pick up into the coating material in the case of iron substrates. This is important, because lower iron pickup reduces the coating thickness requirements in most applications, which results in substantial cost savings.

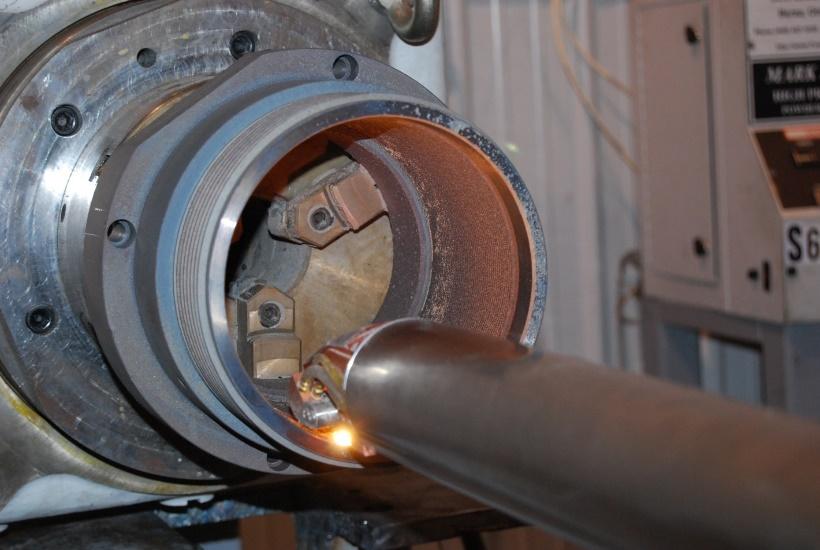

Internal Diameter [ID] Cladding

Our ID cladding capabilities include:

- 3.5” ID or higher

- 40” reach

We have substantial expertise with ID cladding with various coating materials. Please contact our experts to discuss your application.