Synergy Additive Manufacturing, LLC Opens Expansion Facility in Grand Rapids, MI

We are excited to announce that our state-of-the-art Robotic Laser Heat Treating facility is now open! This is one of the largest Laser Heat Treating facilities built to date in the United States. Our new location in Grand Rapids,

Synergy Additive Manufacturing LLC Speaks at RIC-RIT World Remanufacturing Conference

Join us October 12th at the RIC-RIT World Remanufacturing Conference. Synergy Additive Manufacturing LLC's CTO and Co-Founder Aravind Jonnalagadda will join the list of panelists to discuss the benefits of High Speed Laser Cladding/Repair. The two-day event will feature presentations,

Synergy Additive Manufacturing LLC Meets with DSI

Synergy Additive Manufacturing LLC's Co-Founder and CTO Aravind Jonnalagadda meets with the Design and Software International (DSI) team to discuss the future of heat treating with robots and lasers. Take a closer look at how we use Autodesk Powermill and

Synergy Additive Manufacturing Receives Industry 4.0 Grant from the State of Michigan

We are excited to announce that Synergy Additive Manufacturing LLC has received a grant from the Michigan Economic Development Corporation’s Industry 4.0 Technology Implementation Grant program! The funding is part of the MEDC program to ensure that 50% of local

#GDIS 2022

Synergy Additive Manufacturing Co-Founder and CTO Aravind Jonnalagadda and Nitin Kumar are presenting with other industry experts at GDIS 2022. Join us Wednesday, May 18 to learn more about Laser Heat Treating on Form, Trim, & Hot Stamping Dies.

Tool and Die Repair and Engineering Changes Using Laser Cladding

Laser cladding improves the tool life. Laser cladding is an effective tool for the repair and engineering changes on tooling and dies. Compared to conventional welding techniques, laser cladding inputs minimal heat resulting in minimal to no distortion on the

Laser Heat Treating of Hot Stamping Dies

Hot stamping dies are typically hardened throughout, which can create issues during the assembly and testing phase. In order to address any distortions, die makers have traditionally needed to disassemble the entire die, send it for heat treatment, and then

#GDIS 2021

Synergy Additive Manufacturing Co-Founder and CTO Aravind Jonnalagadda and Brian Timmer of Autodie are presenting with other industry experts at GDIS 2021.

LASER CLADDING ADVANTAGES OVER HARD CHROME FOR DIMENSIONAL RESTORATION

Hard chrome plating has long been the preferred method for hardfacing and dimensional restoration of machine parts due to its traditionally recognized benefits.

ONE STOP SHOP

We offer complete turnkey services to fulfill all metalworking needs including CAD, metal forming, laser heat treating, 3D printing, final machining and CMM inspection.

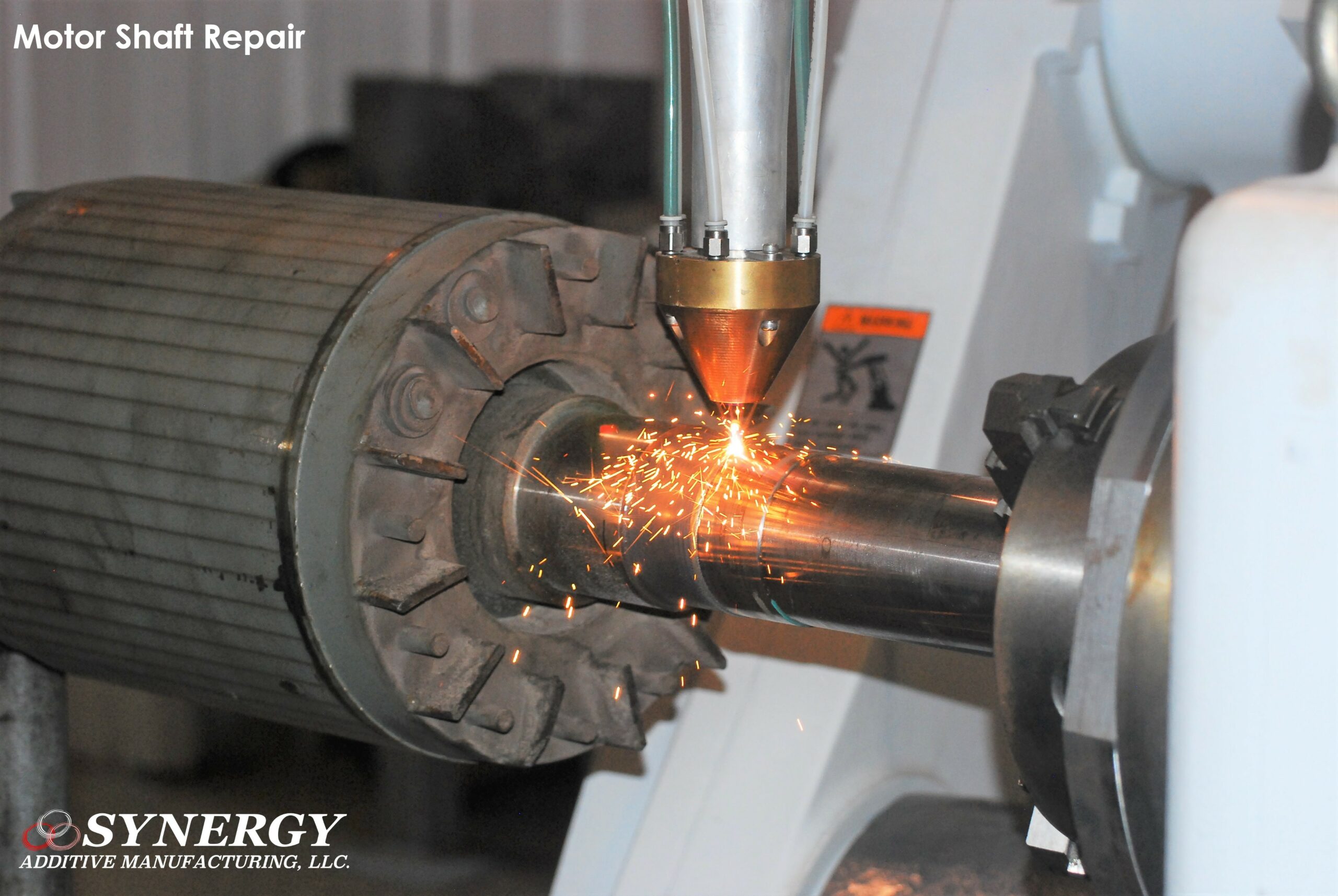

SYNERGY OFFERS ELECTRIC MOTOR SHAFT REPAIR SERVICES

Most typical electric motor shaft repairs require the shaft bearing location to be rebuilt. Wear on the shaft is often a result of bearing failure.

LASER HEAT TREATMENT OF AUTOMOTIVE DIES – BUSINESS CASE AND COST SAVINGS

In the case of automotive dies, the cost savings that result from switching from conventional heat treating processes to laser heat treating are due to the elimination of the hard milling operations that are typically required following the use of those conventional processes.

REVOLUTIONIZING THE AMERICAN HEAT-TREATING INDUSTRY

Industrial Laser Solutions featured SAM in January/February 2019 edition of their magazine. SAM presented the benefits of laser heat treatment which included cost savings and quality improvements.

MOTION+POWER EXPO 2019

Synergy Additive Manufacturing LLC will be headed to the Motion+Power Technology Expo in Detroit next week! The expo runs Tuesday October 15th to Thursday October 17th.

MANUFACTURING DAY SUCCESS

Synergy Additive Manufacturing LLC is beyond pleased to report that Manufacturing Day 2019 was an immense success! It was an absolute pleasure to help educate the next generation of builders, thinkers, and manufacturers.

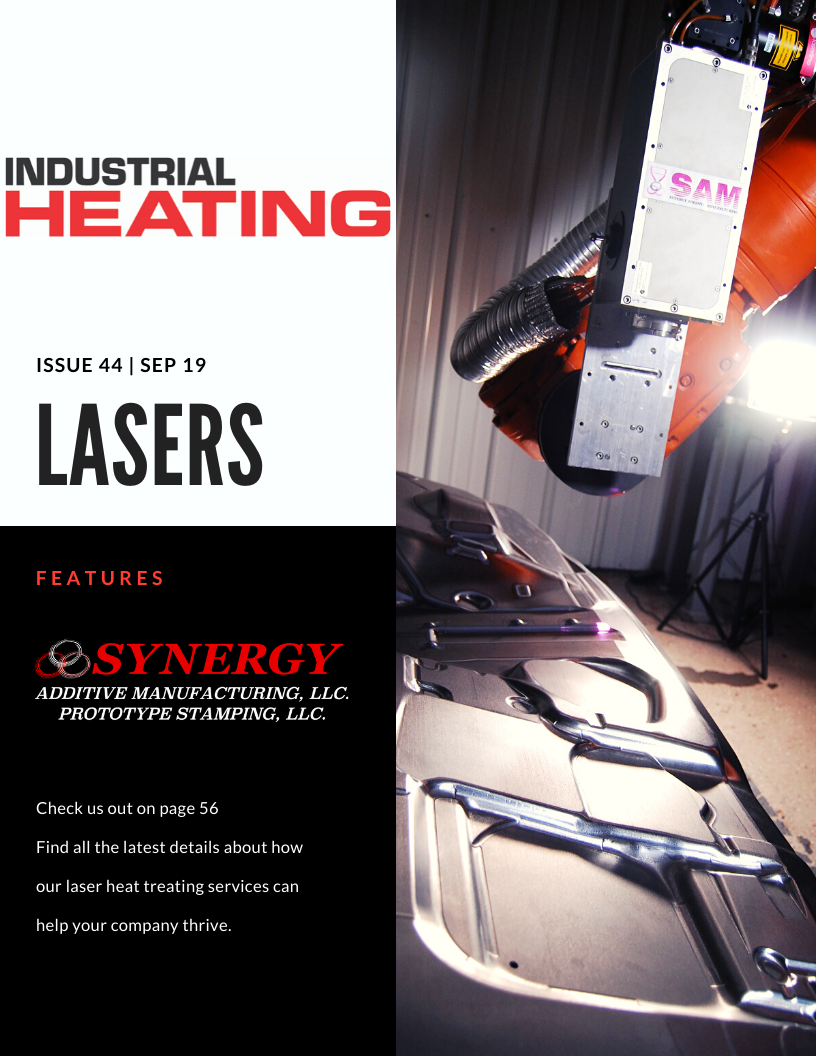

CUTTING AUTOMOTIVE DIE COSTS USING LASER HEAT TREATING

Industrial Heating featured Synergy Additive Manufacturing LLC in September 2019 edition of their magazine! Our article presented the benefits of laser heat treatment which included cost savings, quality improvements, and decreased turnaround times.

WORLD REMANUFACTURING CONFERENCE 2019

Synergy Additive Manufacturing LLC's Co-Founder Aravind Jonnalagadda will be giving a presentation at this years World Remanufacturing Conference in New York (presented by Remanufacturing Industries Council (RIC) and Rochester Institute of Technology).

HOW DO LASER CLADDING AND LASER WELDING DIFFER?

Synergy Additive Manufacturing LLC offers Laser Cladding and Laser Welding. But... what's the difference? Is one better than the other? What are their respective purposes?

GRANT RECEIVED FROM REMADE INSTITUTE IN PARTNERSHIP WITH RIT AND CATERPILLAR

Synergy Additive Manufacturing LLC has received a grant from Remade Institute in partnership with Rochester Institute of Technology and Caterpillar!

WHY LASER HEAT TREATING?

Check out this informative video on all the benefits laser heat treating can provide for your company!

REMANUFACTURING

Remanufacturing can help you improve quality and turnaround time in your industry. See how Synergy can help you save!

“LASER METAL DEPOSITION OF ALUMINUM 7075 ALLOY”

In partnership with Wayne State University, has been published by Madridge Publishers in the International Journal of Material Science and Research.

LASER HEAT TREATING OF HEMMING DIES

If you work with hemming dies and want to protect your investment, watch this short video to see how. With laser heat treating you can ensure consistent hardness, minimal to no distortion, and no post hard milling.

LASER TECHNOLOGY & COVID-19

With the help of Laser Cladding, Laser Heat Treating, and Laser Additive Manufacturing, Synergy is providing an alternative solution for business to replace the more traditional methods that are costly and time consuming. This gives businesses the opportunity to improve their quality and turnaround times to get them back on their feet as soon as possible.

BRINGING TOOL & DIE BACK TO THE UNITED STATES

Over the last decade, most tool and die makers in the United States have been faced with many challenges. A large issue is finding a way to be competitive with die shops overseas.