Synergy Additive Manufacturing Awarded Phase I SBIR

Synergy Additive Manufacturing LLC Awarded Phase I SBIR by US Navy to Develop Advance Coating Solutions for Critical Naval Applications Clinton Township, MI – [June 2025] Synergy Additive Manufacturing LLC has been awarded a Phase I Small Business Innovation

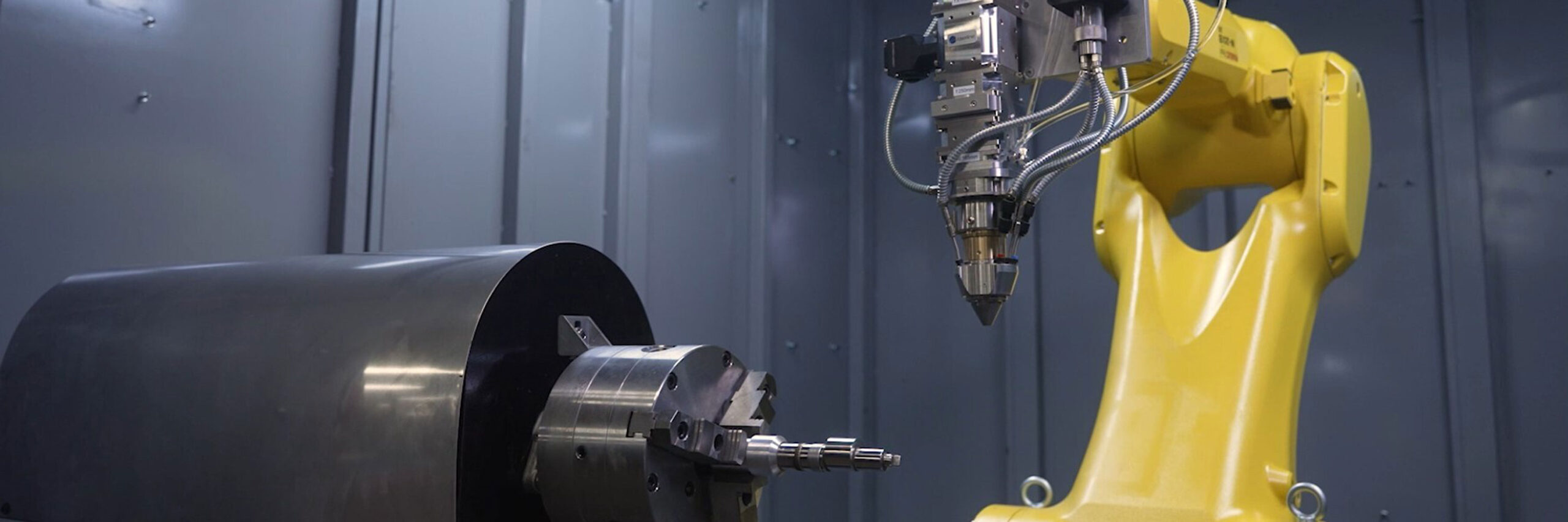

Laser Hardening Process

Laser hardfacing involves using a laser to apply an overlay of hard and wear-resistant material onto functional surfaces. This process enhances the performance and durability of components, making them better equipped to withstand wear and tear. There are various techniques for overlaying metals and hardfacing critical components. Every industrial process possesses its own distinct characteristics and advantages. In this blog post, we will delve into the advantages of utilizing laser cladding technology for hardfacing with Tungsten Carbides. Additionally, we will provide detailed answers to common queries related to this advanced process.

Rockit 606®️ Overlays for Agricultural and Mining Industries

Laser hardfacing involves using a laser to apply an overlay of hard and wear-resistant material onto functional surfaces. This process enhances the performance and durability of components, making them better equipped to withstand wear and tear. There are various techniques for overlaying metals and hardfacing critical components. Every industrial process possesses its own distinct characteristics and advantages. In this blog post, we will delve into the advantages of utilizing laser cladding technology for hardfacing with Tungsten Carbides. Additionally, we will provide detailed answers to common queries related to this advanced process.

Laser Hardening of AISI D2 Tool Steel: A Modern Approach

Laser hardfacing involves using a laser to apply an overlay of hard and wear-resistant material onto functional surfaces. This process enhances the performance and durability of components, making them better equipped to withstand wear and tear. There are various techniques for overlaying metals and hardfacing critical components. Every industrial process possesses its own distinct characteristics and advantages. In this blog post, we will delve into the advantages of utilizing laser cladding technology for hardfacing with Tungsten Carbides. Additionally, we will provide detailed answers to common queries related to this advanced process.