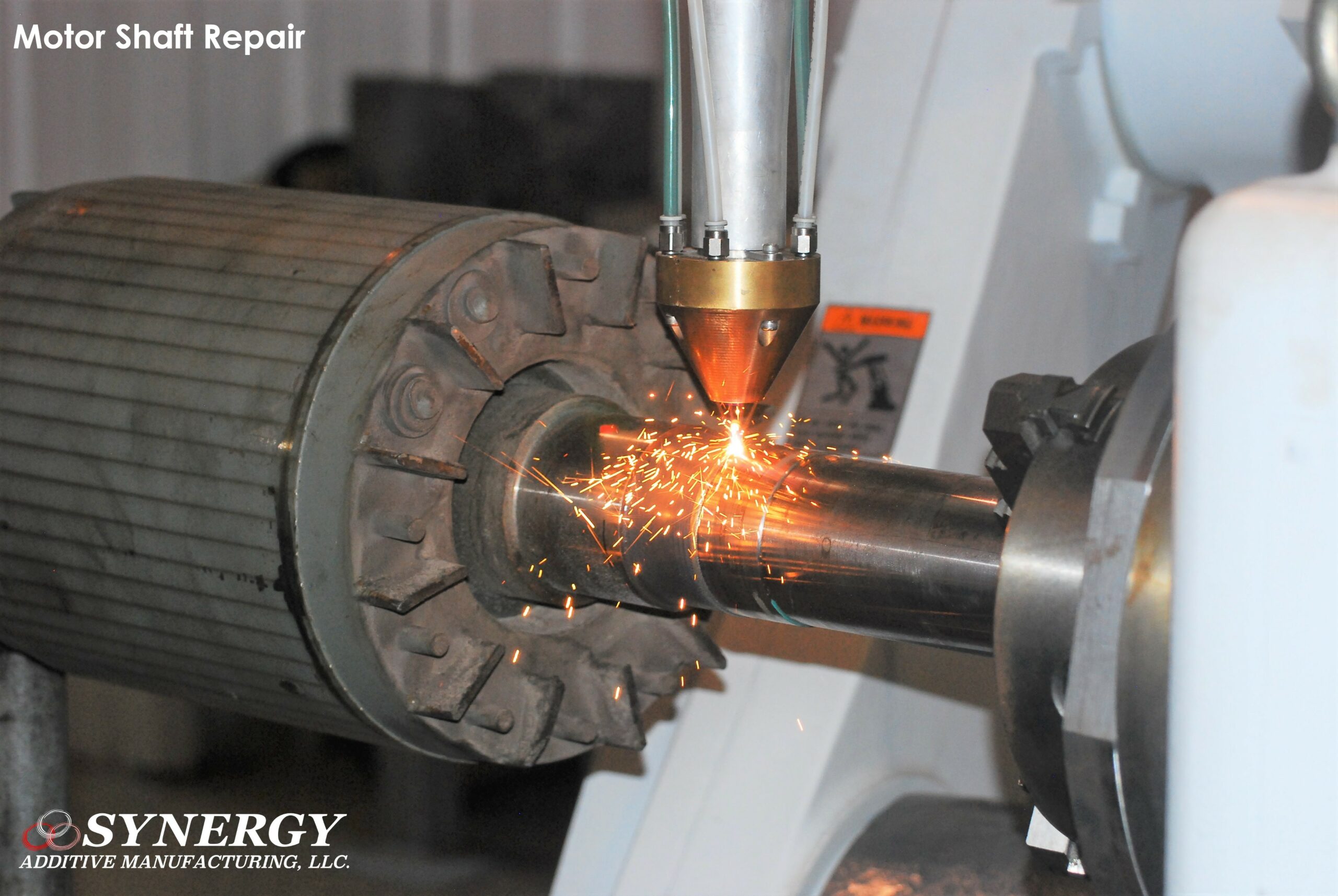

Press and Heavy Equipment Repair with Laser Cladding

In the world of heavy equipment maintenance, efficiency and precision are paramount. When it comes to repairing press components like bearing journals, hydraulic rods, and gears, traditional methods such as TIG, MIG, or submerged arc welding have long been the norm. However, a revolutionary technology known as Laser Cladding is reshaping the landscape of press