SAM LASER CLADDING SERVICES

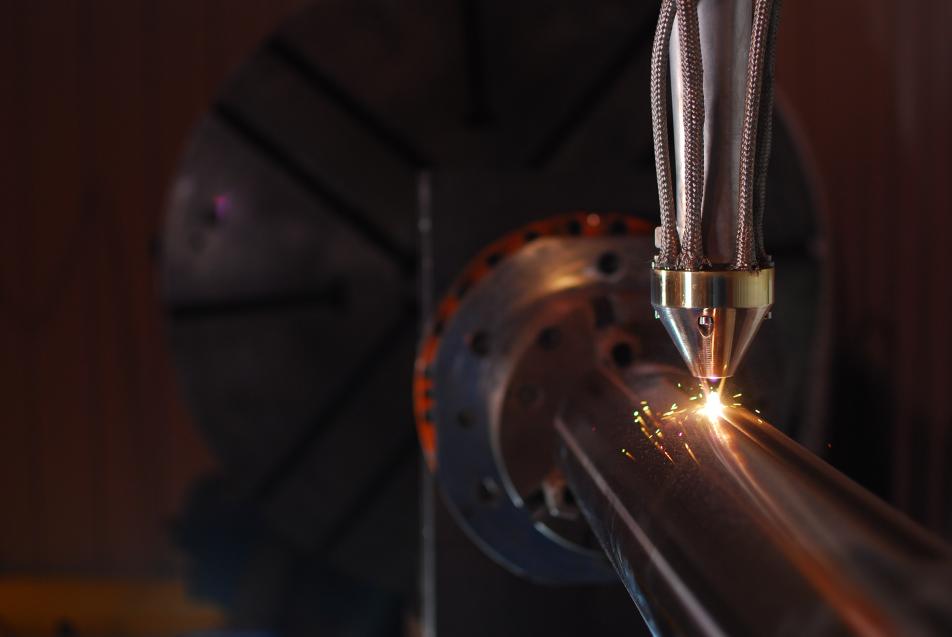

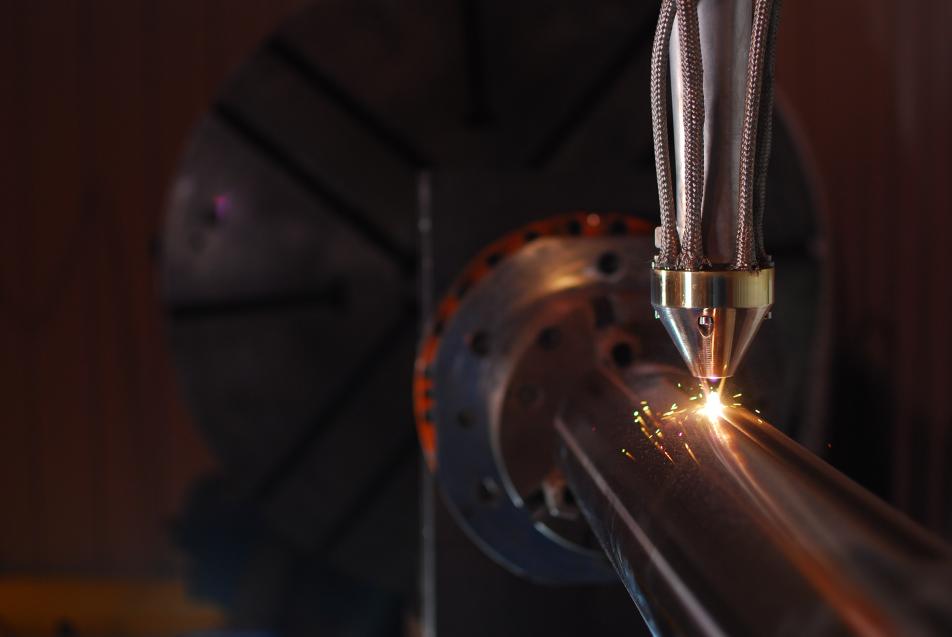

Laser cladding services are categorized as a welding process that utilizes a laser as its main energy source to deposit metals. Laser cladding is used as a way to dimensionally restore or enhance the surface characteristics of the component. Cladding with lasers is focus technology from Synergy Additive Manufacturing (SAM) and our experts are considered leaders in CNC laser applications.

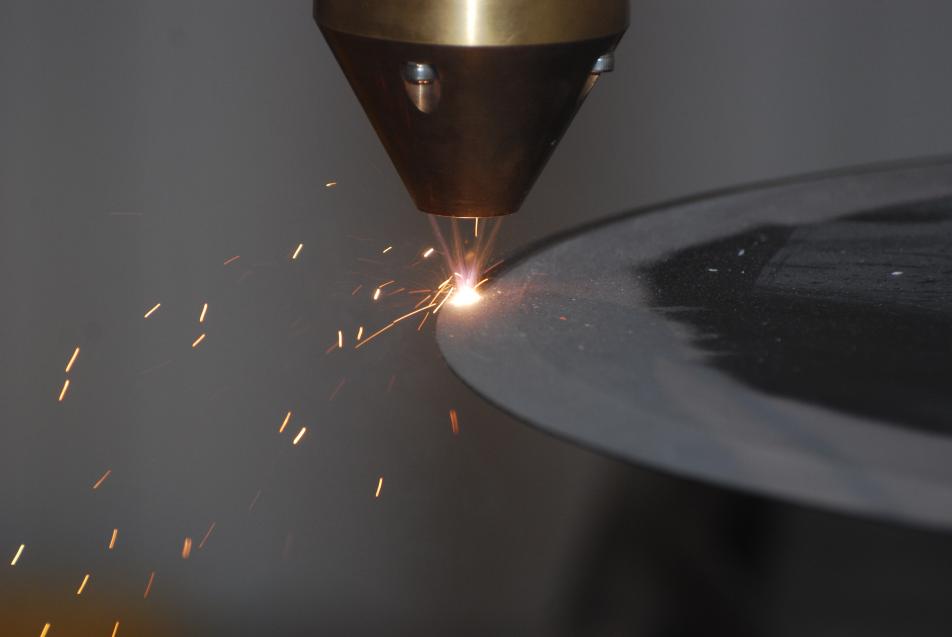

In the laser cladding process, metallic powder material is carried into a melt pool through a powder nozzle. The coating materials, including metals, alloys, and carbide blends, deposit tracks across the working surface to create layers. With fewer layers of application, the laser cladding process introduces opportunities in thickness enhancement.

ENHANCED THROUGH LASER CLADDING

SAM’s laser cladding services surface enhancement applications typically involve the addition of a wear resistant and/or corrosion resistant layer on the substrate material. When compared to other techniques, laser cladding produces significantly lower heat input to the substrate, resulting in minimal distortion and minimal dilution of the coating into the parent metal. In today’s market, laser cladding outperforms conventional TIG welding methods. Greater wear resistance is achieved through laser cladding using carbide coatings due to rapid solidification.

Our laser cladding capabilities at SAM include a maximum part diameter of 5 feet (1.52 m), a maximum length of 20 feet (6.1 m), and a maximum weight of 15,500 pounds (7000 kg). Laser cladding at Synergy Additive Manufacturing is frequently used for wear and corrosion resistance on oil drilling tools, extrusion components, dies, and hydraulic rods, as well as dimensional restoration of machine tool components.

RESULTS WITH LASER CLADDING

For reproducible and stable results, our customers turn to laser cladding because of its numerically controlled processes. Contact the laser cladding experts at Synergy Additive Manufacturing today to find out how we can help restore or enhance your components with our laser cladding techniques.