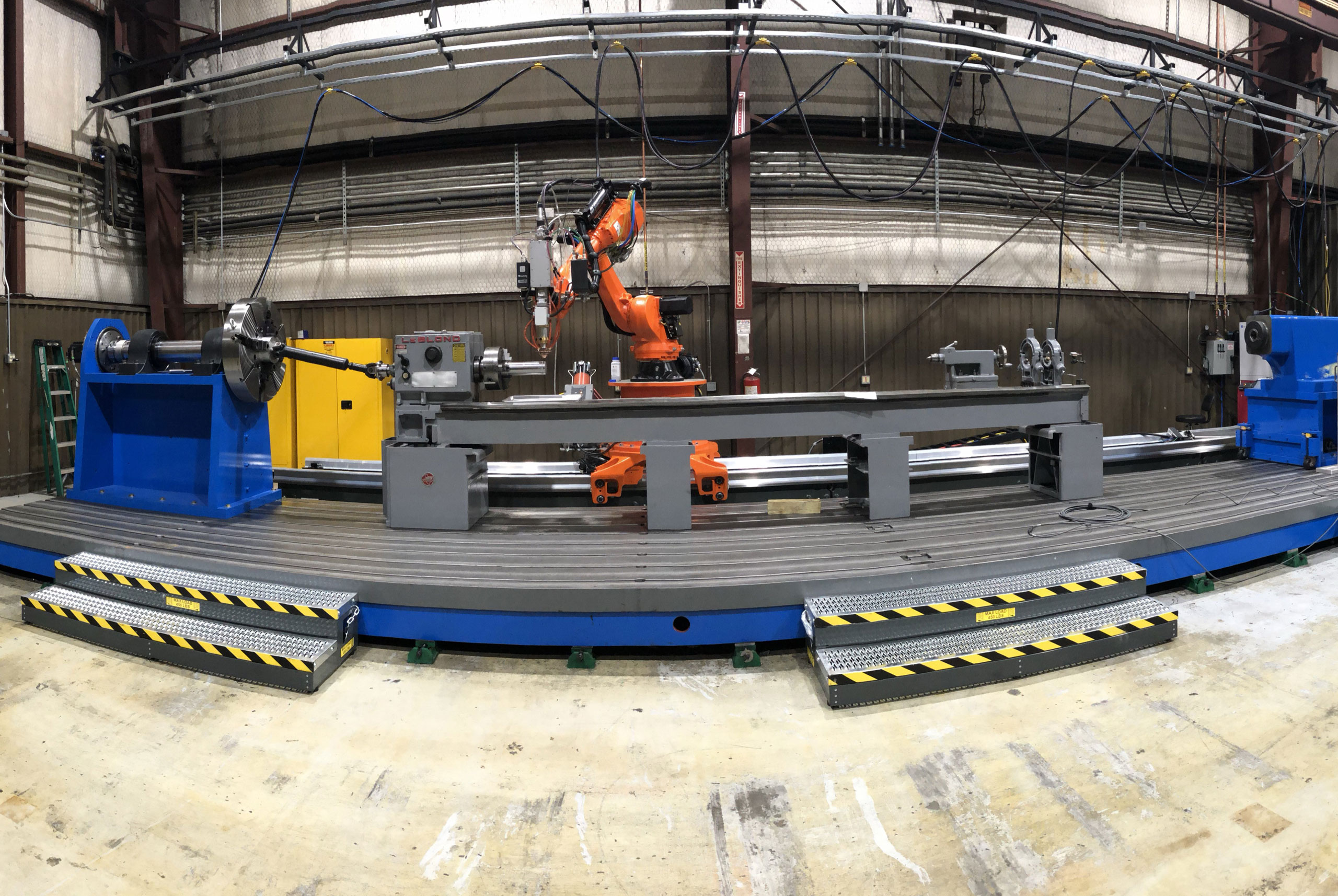

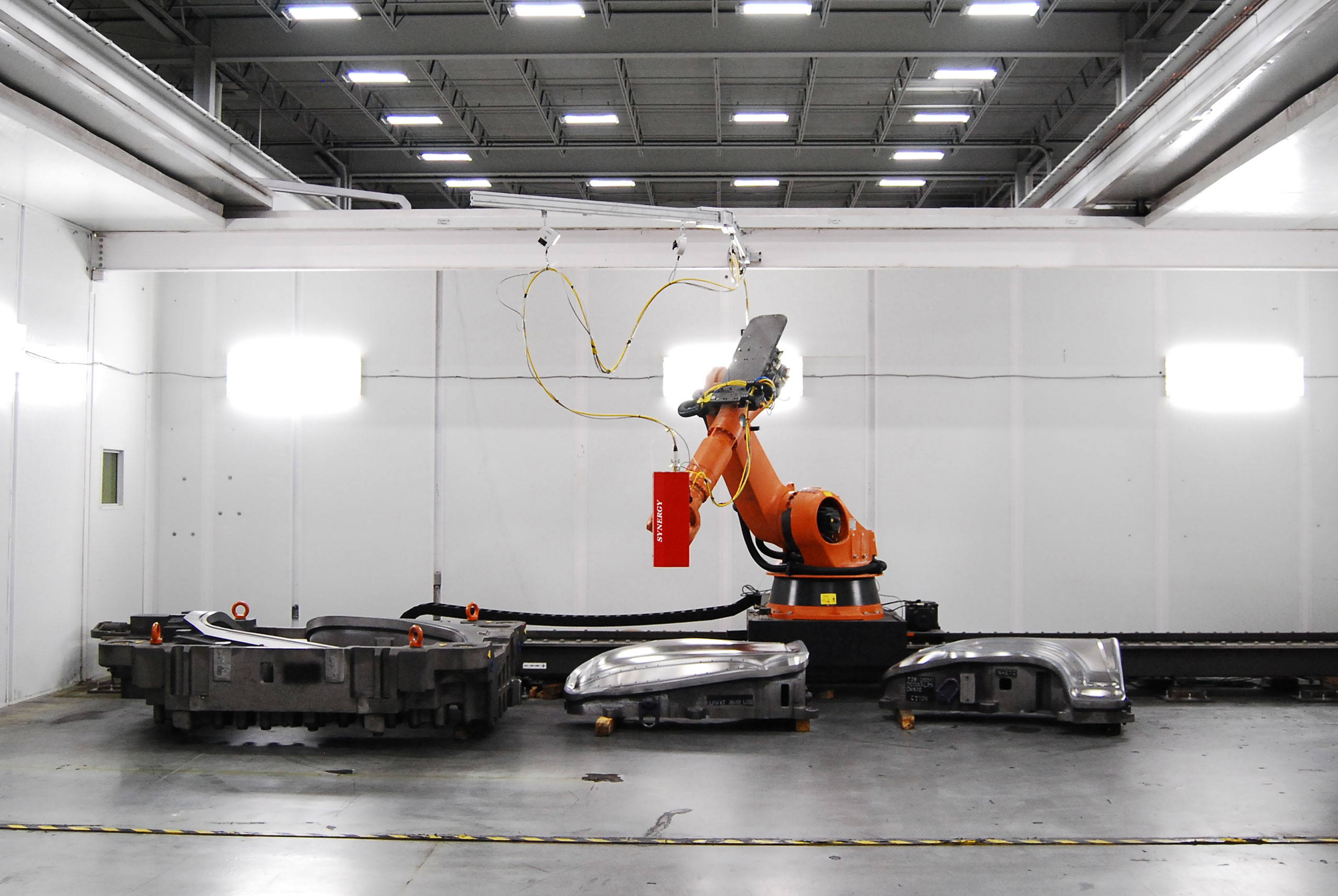

At Synergy Additive, we engineer automation and system integration solutions tailored for the most demanding manufacturing environments. Whether you’re scaling up production, improving part precision, or reducing manual labor, our team delivers turnkey systems that work seamlessly with your existing operations.

Laser Turnkey Equipment That Makes a Difference

Integration Capabilities

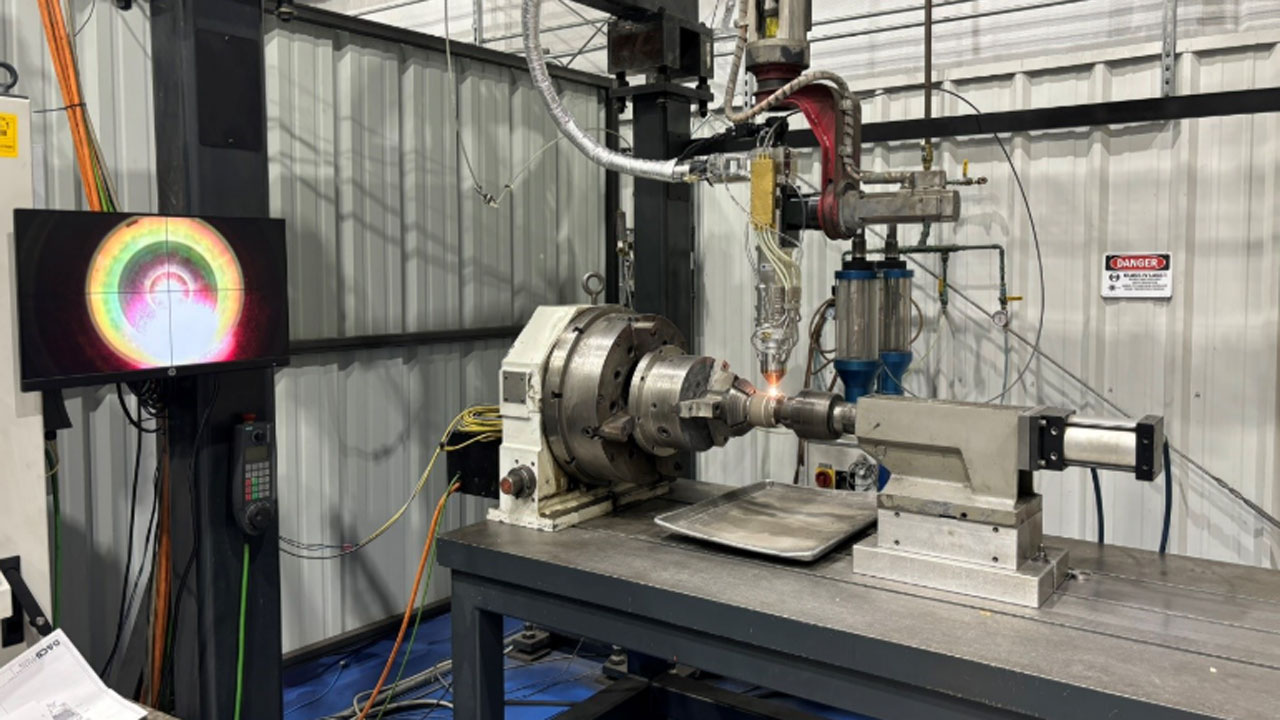

At Synergy, we specialize in custom automation systems designed to meet the exact needs of your operation. Whether you’re looking to upgrade existing equipment or build a fully integrated solution from the ground up, our team delivers systems that perform with precision and reliability.

Our Integration services focus on custom machine building for:

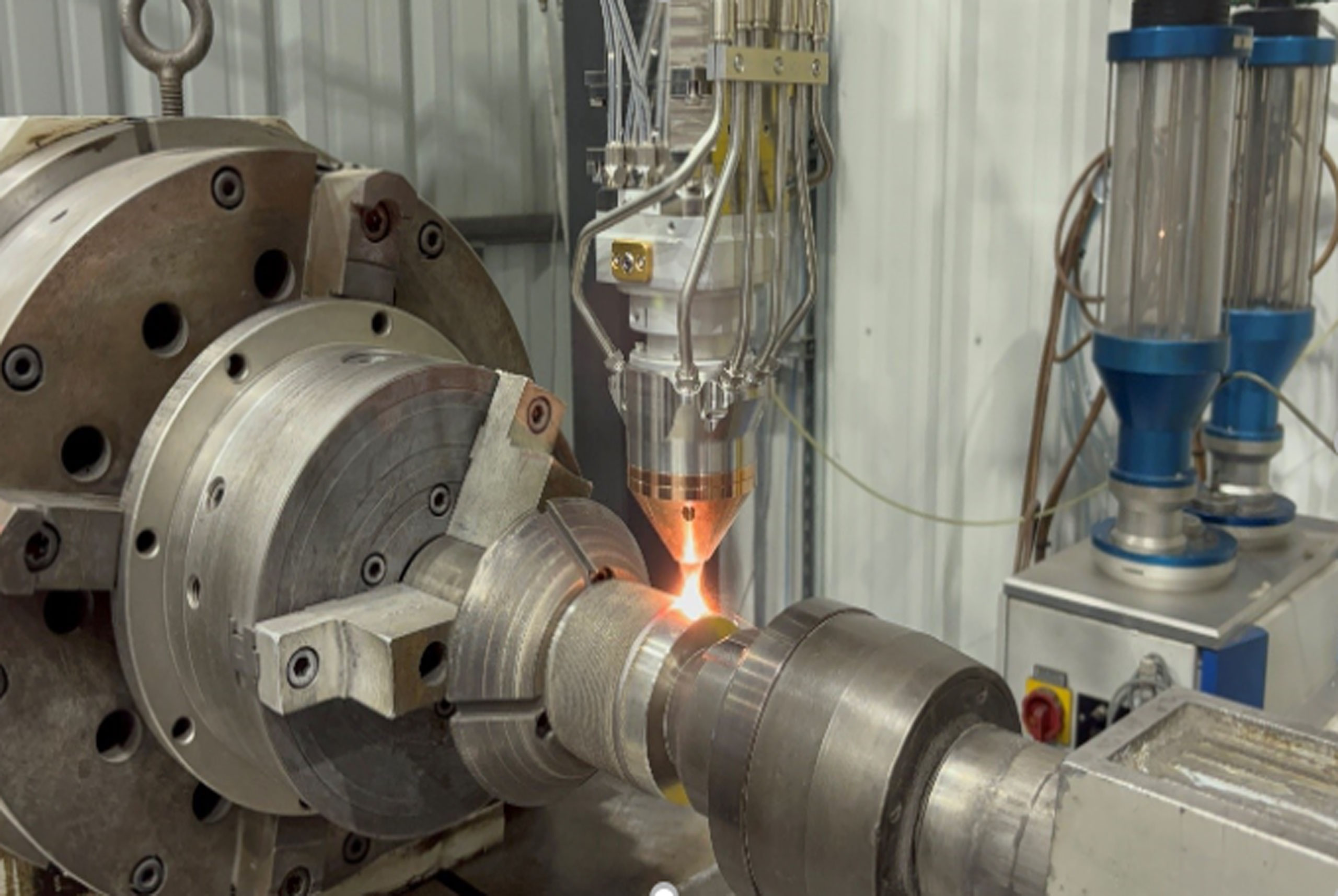

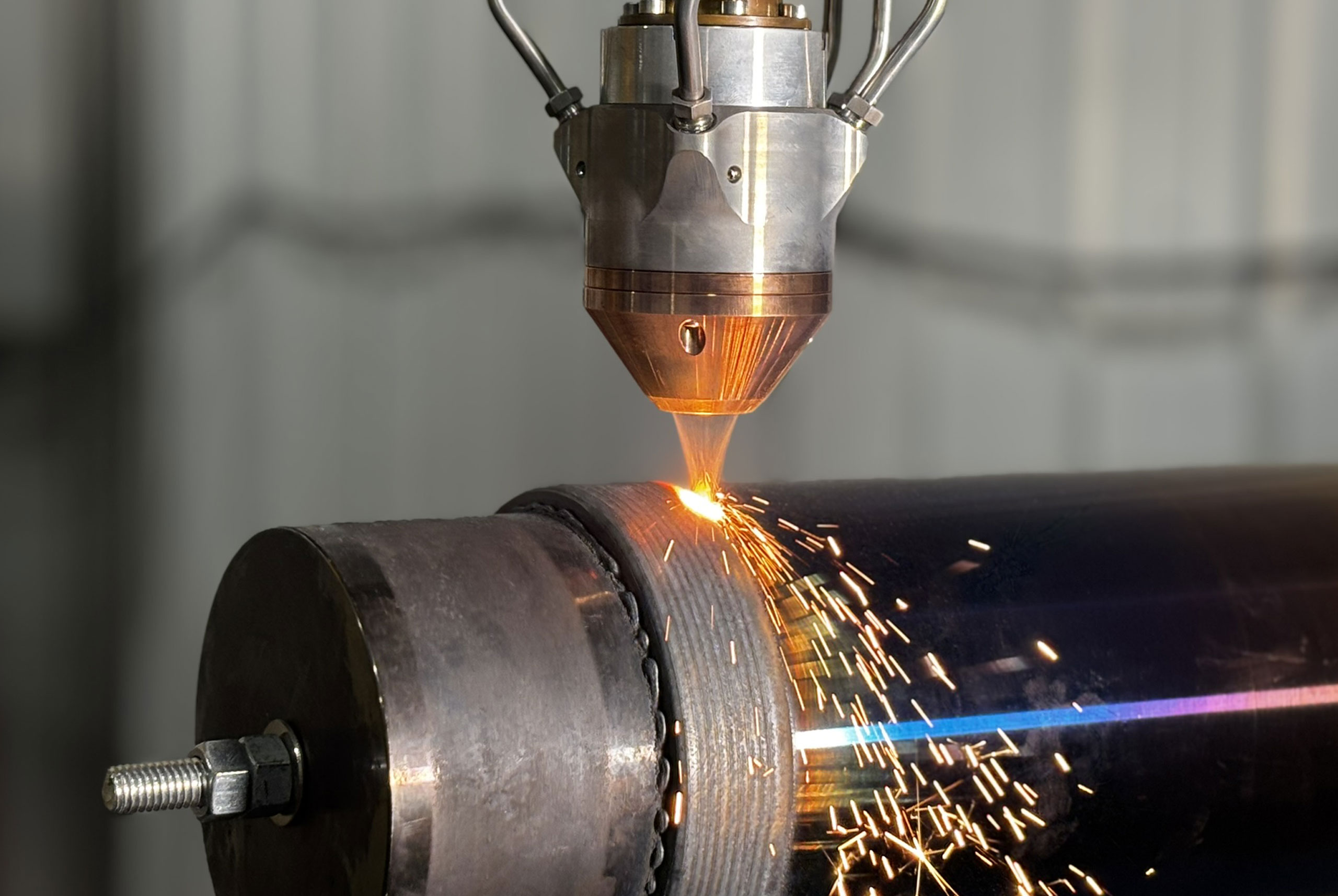

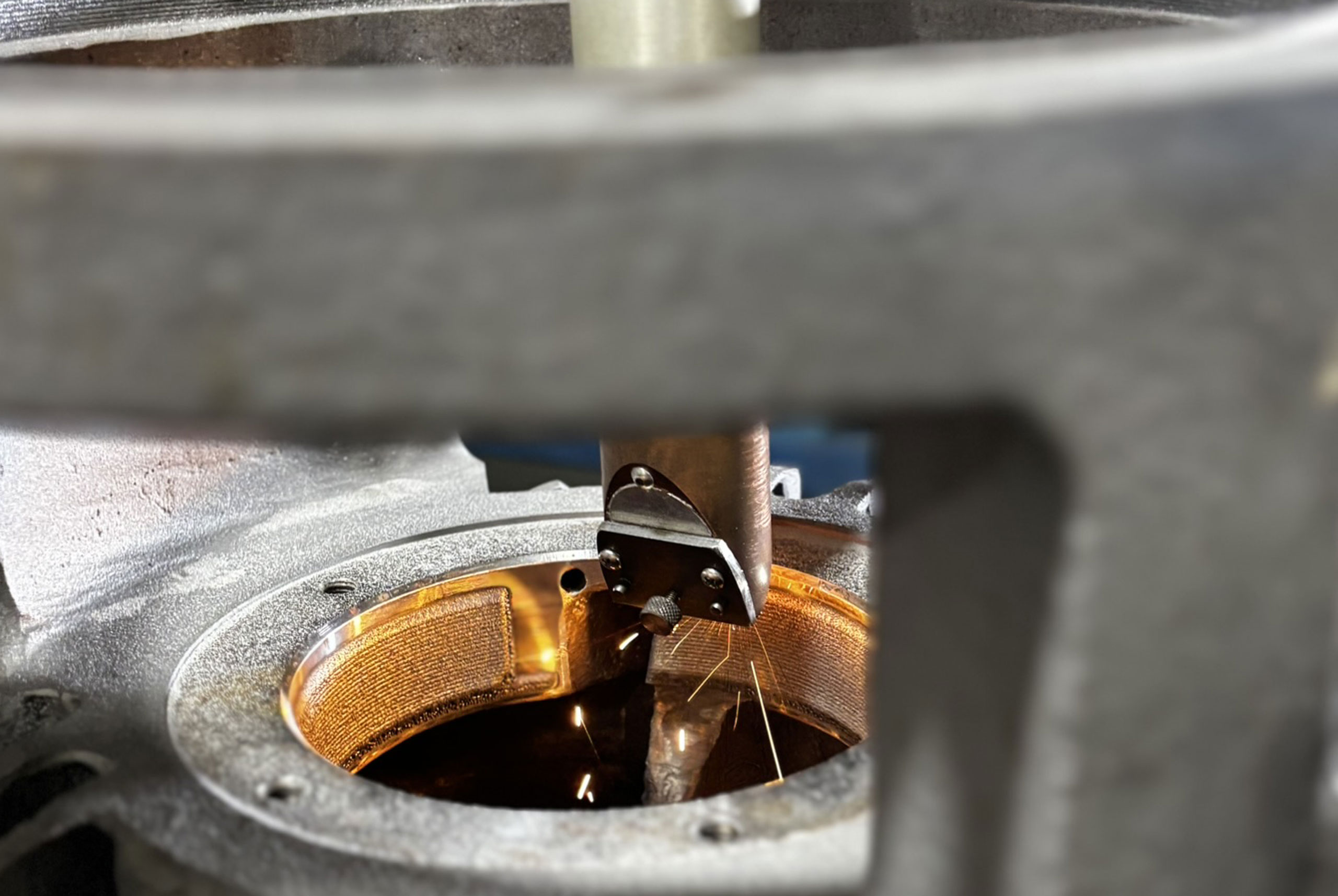

- Laser Cladding

- High Speed Laser Cladding and EHLA (Extreme High Speed Laser Applications)

- ID cladding

- Laser Hardening

- Laser welding

- Laser Cutting

Industries We Serve With Laser Cladding Equipment

-

Aerospace & Defense – Restore and protect critical components like turbine blades and landing gear with wear- and heat-resistant coatings.

-

Medical Device Manufacturing – Enhance surgical tools and implants using biocompatible cladding materials that meet strict precision standards.

-

Oil, Gas & Energy – Extend the life of pump shafts and downhole tools with corrosion- and abrasion-resistant overlays.

-

Automotive & Heavy Equipment – Remanufacture engine and hydraulic components for improved durability and performance under high stress.

-

Tool & Die / Repair Applications – Repair worn tooling surfaces with precision hardfacing to restore functionality and extend lifespan.

-

Valves – Strengthen valve seats and stems with cladding to improve resistance to erosion, cavitation, and chemical exposure.

-

Agriculture – Reinforce wear parts like tillage tools and augers to reduce maintenance and withstand harsh field conditions.

The Synergy Difference: What Sets Us Apart

Test Before You Invest: At Synergy, our deep-rooted job shop experience allows customers to validate their application through short-run to full-scale prototype production—before committing to a purchase. This hands-on approach helps uncover and resolve potential process issues early, while also providing valuable exposure to real-world market conditions. It’s your business case, proven with real results.

Unmatched Process Expertise: In advanced manufacturing, the process is everything. What truly differentiates Synergy from conventional system integrators is our deep expertise in high-power laser applications. With years of hands-on experience, we deliver fully customized, process-driven solutions that are both cost-effective and precisely aligned with your operational goals.

Engineered for Reliability: Every system we deliver is built with performance and longevity in mind. Synergy ensures your equipment is not only fit for purpose but optimized for the demands of your application—delivering consistent results and dependable uptime where it matters most.

Unmatched Process Support: High-power laser cladding and other advanced applications often involve complex variables that can affect metallurgical integrity. That’s why our commitment extends far beyond the hardware. Synergy offers industry-leading support—not just for the equipment, but for every stage of your process. We’re here to ensure you succeed, every step of the way.

Ready to Automate Smarter?

Let’s talk about how system integration can drive real performance gains for your operation. Schedule a Consultation or Request a System Review today!